Relationship between semiconductors, integrated circuits and chips

Semiconductors refer to materials with conductivity between conductors and insulators at normal temperature. Common semiconductor materials include silicon, germanium, gallium arsenide, etc., which are currently used as the basic materials for manufacturing chips.

Integrated circuit (IC) is a specific circuit or system that integrates active devices such as transistors and diodes and passive devices such as resistors and capacitors into semiconductor chips and packages them in a shell according to a certain electrical interconnection process.

Chip, also known as microcircuit, microchip, is the general name of semiconductor component products. It is the carrier of integrated circuit, which is divided by wafer and is the physical object of electronic products with specific functions. Including integrated circuits (CPU, GPU, FPGA, ASIC, memory, MCU, power management chip, etc.), optoelectronic chips, power semiconductor chips, MEMS chips, etc.

Overview of semiconductor manufacturing industry chain

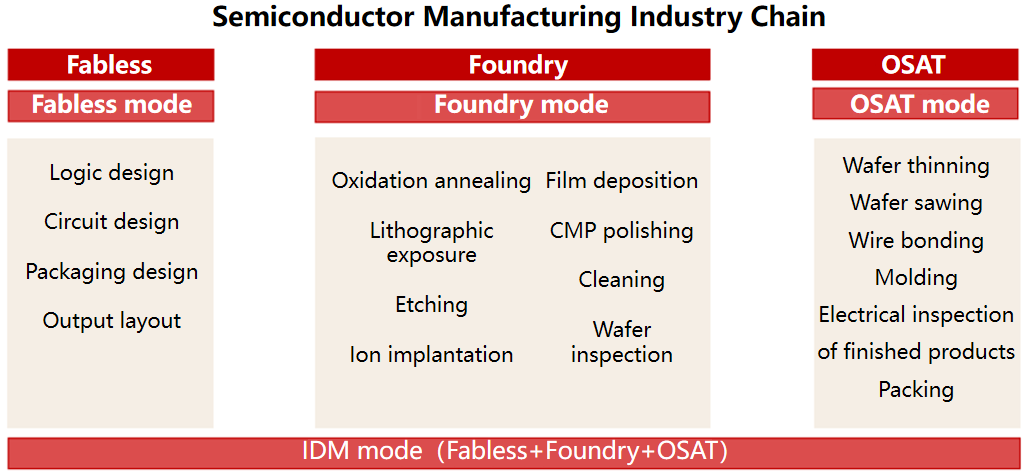

The semiconductor manufacturing industry chain is mainly divided into chip design, wafer manufacturing and packaging testing.

The semiconductor manufacturing industry chain includes three major links: chip design, wafer manufacturing, packaging and testing. The business model is mainly divided into vertical division of labor (Fabless, Foundry, OSAT) and IDM models. Fabless focuses on the chip design process and outsources the production and packaging testing process. The chip design enterprises have the asset-light advantage. Foundry focuses on the field of wafer foundry, and the foundry manufacturers undertake the subcontracting orders of the chip design enterprises, and form the scale effect. Such enterprises have a large investment scale, and the operating cost of maintaining the normal operation of the production line is high. OSAT focuses on the packaging and testing process. IDM refers to the manufacturers undertaking the design, manufacturing Encapsulate the whole process of testing. This mode has the advantage of industrial chain integration.

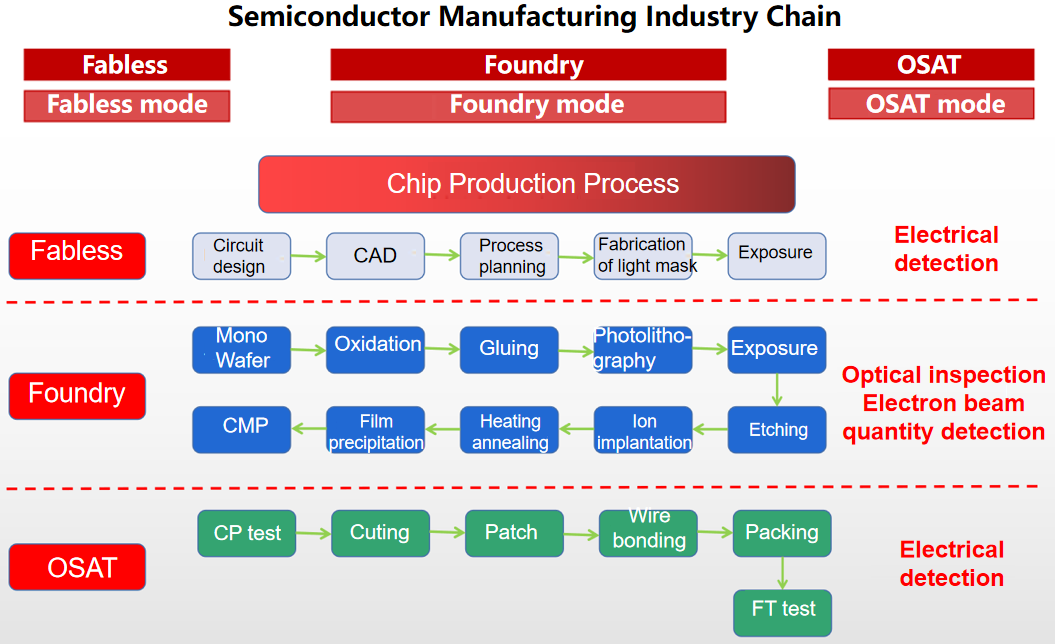

Chip production process

IC Test

Semiconductor test runs through the whole process of chip production to ensure that the chip meets the requirements of customers. Combined with the three processes of wafer manufacturing, the tests corresponding to the relevant processes are mainly divided into chip design (design verification), wafer manufacturing (process control test, wafer ring test), and packaging test (aging test, electrical test). The design verification mainly tests the function design of the chip sample. It tests the system design, logic design, circuit design, physical design and other different links. The process control test tests the main steps in the wafer production process. The CP test tests the logic function and pin function of the chip. The aging test and electrical test FT test are the final test links of the chip, which occurs after the completion of packaging, It mainly tests the function and electrical parameters of the packaged chip to ensure that the chip function and performance indicators meet the design specifications.

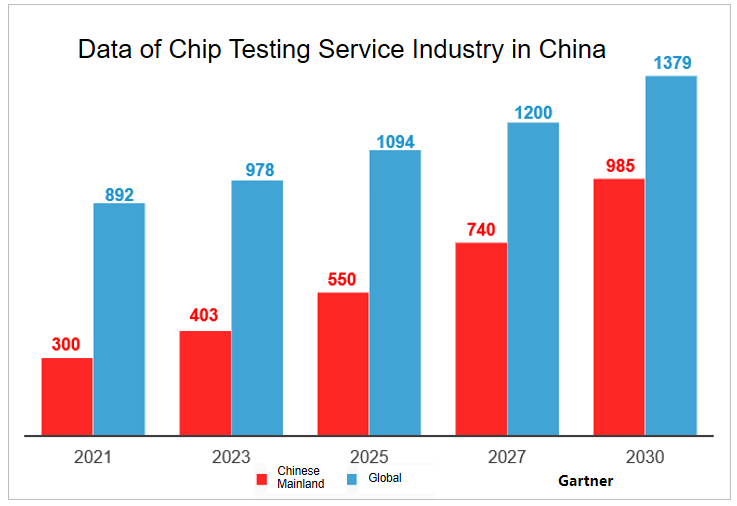

Development of chip testing service industry in China

According to the comprehensive prediction of Gartner Consulting and CLSA, the global chip test service market is expected to reach 109.4 billion yuan in 2025, of which the Chinese chip test service market will reach 55 billion yuan, accounting for 50.3%. There is a huge growth space of more than 25 billion yuan in five years.