In the event of product finalization, production transfer, factory transfer, or resumption of production after production suspension, significant changes in structure, materials, or processes, or contractual provisions, electric vehicle motors shall undergo inspection. The number of sampled products shall be 2. If any item fails, the number of samples for reinspection of the item shall be doubled. If the inspection is still unqualified, it shall be determined as unqualified. The reliability test inspection items include: temperature, humidity, and thermal insulation resistance, fixed frequency vibration and swept frequency vibration, salt spray, waterproof, and dustproof.

When conducting reliability tests on motors, the following technical conditions should be met:

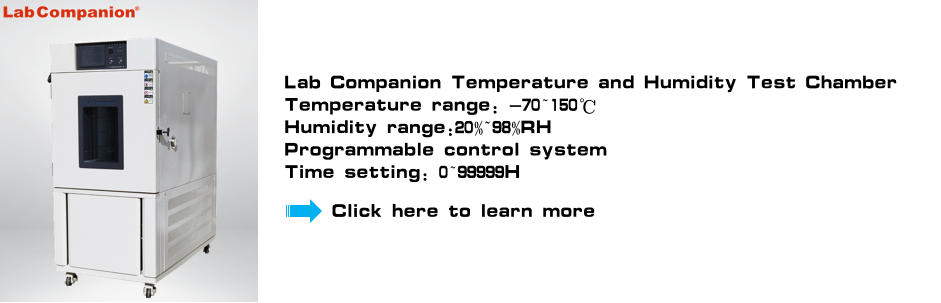

Temperature: When the ambient temperature is between - 20 ℃ and+40 ℃, the motor and controller can operate continuously for a long time.

Humidity: The motor and controller can work normally when the relative humidity does not exceed 100%. The motor and controller should be able to work safely even if their surface temperature is lower than the dew point, even if condensation occurs on the surface of the motor and controller.

Salt spray: As a product of automotive electrical equipment, it should have a certain salt fog resistance and meet the relevant provisions in GB/T 2423.17.

Waterproof and dustproof: When exposed to rain and washed with high-pressure water, the construction, installation, and ventilation methods of the motor and controller should ensure that the motor and controller are not damaged.