With the development of the global economy, the application of new energy is becoming increasingly widespread, including lithium battery technology used in automobiles or other consumer fields. With high energy density and light weight, batteries have been the best choice for fixed storage of renewable energy, as well as for automotive or electric vehicle applications. Each battery cell and module requires many extreme tests to determine the power and service life of the battery and its components. Lab Companion provides reliability testing equipment and solutions for lithium ion battery testing.

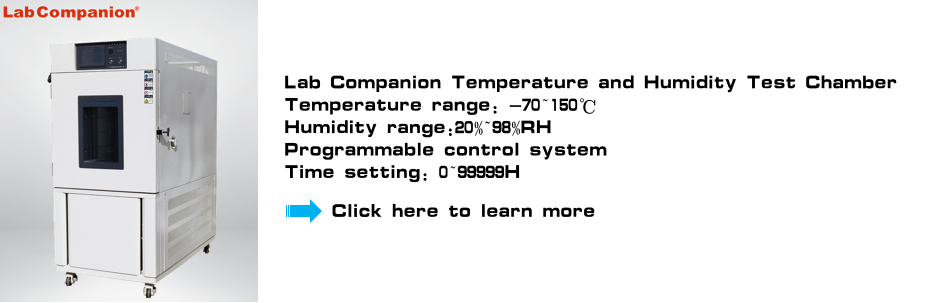

In the life testing of lithium batteries, it is necessary to determine the seasonal aging characteristics of component cycles and the aging characteristics under changing environmental conditions through changing environments such as temperature cycling. During the reliability testing process, lithium battery components are subjected to alternate temperature tests under different conditions, usually using a temperature and humidity test chamber.

In performance test of lithium battery, an environmental simulation chamber can be used to test the performance of lithium batteries in an ambient climate with a temperature of - 30 ℃ to 60 ℃ and a relative humidity of up to 96%. Generally, the duration of test varies, and under extremely severe conditions, some testing can last several months. Common constant or cycling temperature and humidity test chambers will be used.

Lab Companion provides safety test for lithium batteries. The most common hazardous accident of lithium batteries is explosion and fire. How to ensure the safety of lithium batteries is an important factor that manufacturers and regulators need to consider. During the test process, lithium batteries will generate accumulated joule heat, resulting in a temperature rise in the battery, leaving the internal materials of the battery at risk of thermal runaway. Therefore, it is necessary to place lithium batteries under various temperature conditions and changes such as high temperature, low temperature, and temperature cycling, and integrate them with the charging and discharging system to conduct overcharge, discharge, and short circuit tests at various temperatures to avoid explosion hazards.

Thermal shock cycles and damp heat tests are common test items in the lithium battery industry. Constant temperature and humidity chambers, thermal shock test chambers, and high and low temperature alternating humidity and heat test chambers are common test equipment. Salt spray and low air pressure projects are rarely used, but salt spray test chambers are also widely used.