What is lidar?

Lidar is a system integrating laser, global positioning system (GPS), and IMU (inertial measurement unit). Compared with ordinary radar, lidar has the advantages of high resolution, good concealment, and stronger anti-jamming ability. With the continuous development of science and technology, the application of laser radar is more and more extensive. It can be seen in robot, driverless, driverless vehicle and other fields. Lidar is the main choice of high-level intelligent driving vehicles, and the independent development of domestic lidar technology has important strategic significance.

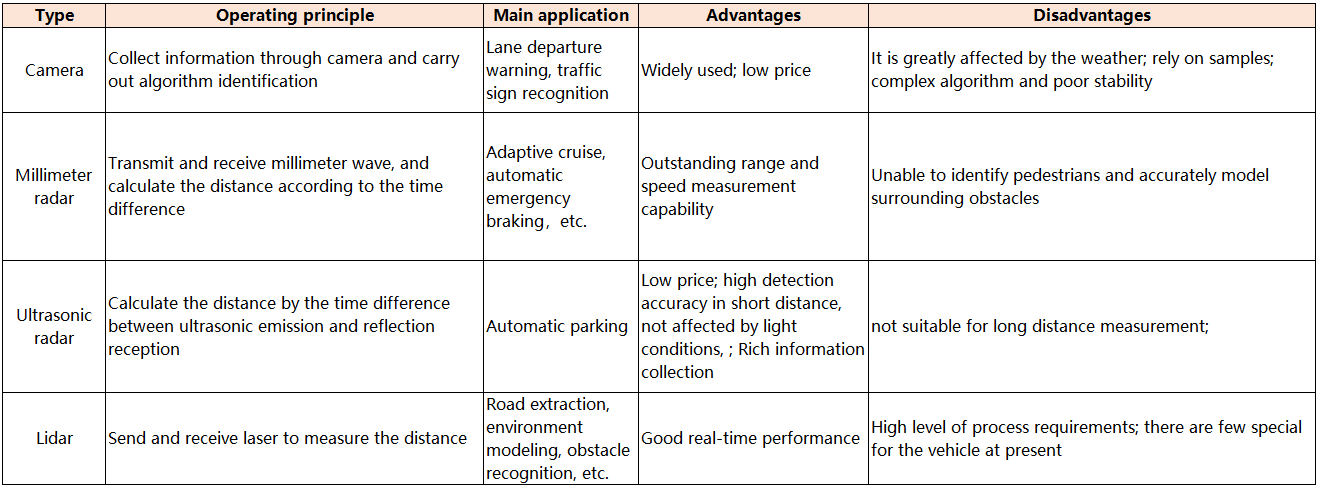

Comparison between different type of vehicle radar

The development of vehicle radar industry

From the perspective of the industrial cycle, the car size level laser radar has entered the rapid development stage after a period of technology initiation, introduction and exploration. It can be seen that there is an industrial symbiotic relationship between the car size level laser radar and the development of intelligent connected vehicles. This symbiotic relationship will be further strengthened with the penetration and improvement of advanced autonomous vehicle.

From the product position, it is of strategic significance to ensure the competitiveness of the industry chain and the stability of the supply chain of the vehicle laser radar.

Judging from the competition pattern, the first-mover advantage of foreign countries is not significant, and the gap at home can be catched up. The vehicle-level laser radar will enter the era of great competition.

The vehicle laser radar enterprises should grasp the four key words of "vehicle-gauge", "mass production", "performance" and "price", and at the same time improve the autonomous and controllable level of vehicle laser radar to prevent being contained.

AECQ100 certification [Lab Companion Laboratory]

Before any chip enters the production stage, it must pass a series of electrical, service life and reliability stress tests. For automotive chips, product testing is much more rigorous than industrial or commercial chips. The goal of AEC-Q100 is to improve the yield of products. Due to more stringent testing, more and more industrial customers give up standard industrial products and choose AEC-Q100 certified components.

Lab Companion has rich experience in electronic verification at the vehicle specification level to help prevent various possible conditions or potential failure states of the product, and guide the parts supplier to adopt chips that meet the specification in the development process. Through AEC-Q100, the quality and reliability of each chip case shall be strictly confirmed to confirm whether the product data sheet, use purpose, function description, etc. proposed by the manufacturer meet the requirements of the initial requirements, and whether each function and performance can be consistent after continuous use.