Before officially entering the market, an SSD(Solid State Drive) must undergo a variety of tests, including aging test and high temperature test. These two tests have very strict requirements on the quality and reliability of the chip. After all, they are related to the data storage performance. Only when the SSD pass the standard test can they enter the market with fist class quality.

But after visiting so many SSD production factories, we found that the status quo of two test in many factories are:

(1)The aging test and high temperature test are conducted separately, so that it costs too much time to finish.

(2)Some harsh conditions, such as the harsh temperature required for industrial control product testing, or the testing environment under certain humidity and pressure, cannot be fulfilled by the equipment in most factories at present.

In general, the problem is that the product testing time is long and the testing environment is not good enough, which leads to the extension of the delivery date and the increase of the product repair rate. Is there any way to solve these problems at one go?

The answer is yes!

Firstly, let's see two major features which the test equipment should have.

Perfomance

In the customized SSD temperature aging test chamber, aging test, constant temperature test or rapid temperature change test can be conducted at the same time;

The test temperature standard can reach the industrial level, the maximum temperature can reach +150 ℃, the minimum temperature can reach -70 ℃, and the temperature regulation program is automatic;

In the process of temperature change, water vapor will also be formed, which can create harsh test environment conditions.

Operation

When the product is tested under severe temperature, humidity and pressure, the aging life test will be accelerated and the overall product life test time will be shortened;

It can detect the sealing and pressure resistance of the packaging of the electronic components, so as to check the environmental adaptability and working pressure adaptability of the product!

Customized inner chamber structure ensures that the temperature, humidity and pressure of the product are balanced during the test!

The most important thing is the integrated design of the whole equipment circuit, which is easy to operate and maintain.

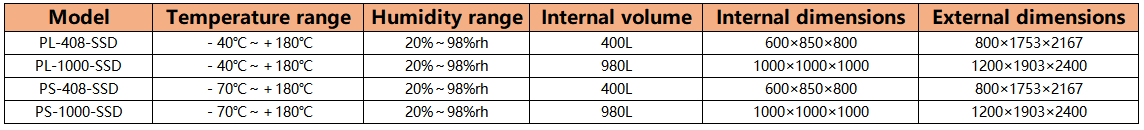

Now, Lab Companion has launched serie test chamber specicial for the SSD, the major features are as follow.

High performance that can carry out high load heating reliability test with maximum heating load up to 4500W, suitable for SSD high load heating reliability test.

Faster heating and cooling rate than normal test chamber: heating rate 7℃/min, cooling rate 3~5℃/min. Humidity range:20%~98%RH.

Balanced temperature and humidity control system (BTHC), dual PID and steam partial pressure control, mature technology and high precision.

Energy saving.

Network control and data acquisition can be carried out through the interface(RS-485/GPIB/Web Lan/RS-232C).

Standard left and right cable holes (50mm), whic is convenient for connecting the sample and conducting multiple measurements.

Color LCD touch screen control system. The controller can select two types of control, namely, constant value control and program control, to apply different applications

100 modes can be set for program control, and 99 steps can be set for each mode. Repeat cycle up to 999 times.

Optional pressure relief valve, smoke sensor, and other additional function, to meet our customers various demand.