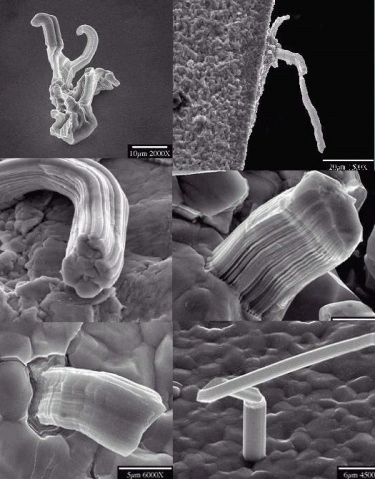

In the process of lead-free component manufacturing, in order to maintain the solderability of components, pure tin plating is often used to replace the original tin lead, but after a period of time, at room temperature, pure tin plating will grow dendritic protruding, called tin whisker (whisker). The tin whisker is completely different from the ion migration we often say. Please note that if the length of the tin whisker is too long, it will cause short circuit between conductors or components. At present, relevant tin whisker detection standards have been formulated and environmental test methods of tin whisker can help relevant enterprises test the inhibition method of tin whisker. And the method to avoid tin whiskers to meet the relevant lead-free process of heavy metal requirements and standards, in the high-density construction of electronic products (mobile phones, PDA, MP3, automotive electronics, etc.), the requirements of tin whiskers is urgent, Hongzhang technology hopes that through the collection and sorting of relevant information, to help customers import tin whiskers test as soon as possible, enhance and strengthen the competitiveness of the enterprise itself.

No.1 There are 13 factors affecting the growth of tin whiskers

1. Grain size

2. Residual stress

3. External stress

4. Organic matter including: carbon, sulfur, oxygen... Etc.

5. Hydrogen and water gather

6. Thermal stress

7. Electric and magnetic fields

8. Nucleation

9. Electroplating solution

10. Electroplating conditions: current density, electroplating pulse

11. Temperature

12. Humidity

13. Time

(1) Reasons for the easy growth of tin whiskers:

1. Bright tin is easy to grow tin whiskers

2-1. The surface of pure tin is vulnerable to natural crystal growth

2-2. The higher the purity of tin, the greater the chance of forming tin whiskers

3. Chemical stress is the most important driving force for the spontaneous growth of tin whiskers

(2) Tin whisker definition:

A. Length >10um

B. Consistent cross-section shape

C. There are tombs and horns

D. Length/width ratio >2

E. It is striped

(3) Calculation method of tin whisker length :

A. Jdec-22a121 magnitude method

B. JDEC-201 &IEC magnitude method

(4) Length limit of whiskers:

<25um, <30um, <45um, <50um, <60umJESD201 The length of tin whisker is different according to different test methods.

No.2 The inhibition or reduction of tin whiskers can be sorted out in 9 ways

1. Add a barrier layer, such as a nickel layer, between copper and tin

2. Copper → nickel → Palladium → Gold (forming a barrier layer)

3. Use a nickel-palladium lead frame

4. Mist coated tin (5um)

5. Tin plating (10um)

6-1. Spray tin or tin plating (8~12um) within 24 hours, quenching (annealing) fire (150℃) 1~2 hours (Post baking)

6-2. Tin plating (>7.5um) + post-drying treatment

7. Increase the silver content in tin plating

8. The temperature stress introduced in the welding process should be as low as possible

9. Reduce the copper content of pure tin or exposure to copper

No.3 Introduction of tin whisker test method:

A.Storage at room temperature:

1. Office room temperature, 1000h

2.20~25℃/30~80%R.H, 1500h, 4230h

B.High temperature storage:

1.55℃/2years, 3400h

2.90 ℃ / 400 h

C.Temperature and humidity storage:

1.50℃/85%R.H, 1500h

2.51℃/85%R.H, 3000h

3.55℃/80~95%R.H, 4230h

4.55℃/85%R.H, 2000h, 4000h (Check once at 1000h)

5.60℃/85%R.H, 4000h

6.60℃/87%R.H, 3000h

7.60℃/90±5%R.H, 3000h

8.60±5℃/93 (+2/-3) %R.H, 1000h, 4000h

9.60℃/95%R.H, 1000h, 1500h

10.85℃/85%R.H, 500h±4h

D.Temperature Shock (TST) :

1.-55 (+0/-10) ℃←→85 (+10/-0) ℃, 20min/1cycle, 1500cycles (Check once for 500cycles)

2.85±5℃←→40 (+5/-15) ℃, 20min/1cycle, 500cycles

3.-35±5℃←→125±5℃, dwell for 7min, 500±4cycles

4.-55 (+0/-10) ℃←→80 (+10/-0) ℃, stay for 7min, 20min/1cycle, 1000cycles

E.Temperature cycle (RAMP) :

1.-40℃ (30min) ←→85℃ (30min), RAMP: 5℃/min), 2000cycles

2.-40℃ (15min) ←→125℃ (15min), RAMP: 11℃/min), 500cycles

3.-40℃ (15min) ←→125℃ (15min), RAMP: 15℃/min), 54290cycles

No.4 Test equipment:

A. Constant temperature and humidity test chamber

B. Temperature shock test chamber

C. Temperature cycle test chamber